TITANIUM is a fascinating metal with many interesting qualities. Let's look at some quick pros and cons of the metal.

PROS

CONS

For many, TITANIUM is primarily thought of in relation to weight: it makes bikes light.

Of course, TITANIUM is actually about 2/3 heavier than aluminum--the density of a given material is only one variable that needs to be taken into consideration when designing a bike frame. As noted above, TITANIUM is special primarily because of its high strength-to-weight ratio. Depending on the alloy, TITANIUM tends to exhibit both higher yield and tensile strengths than steel, while being half as dense (Nuclear-Power.net).

Two other crucial considerations are TITANIUM's low modulus of elasticity (MOE) and high fatigue limit. Modulus of elasticity measures a material's resistance to bending force, so TITANIUM's low rating here essentially means that it's much less stiff or rigid than steel (by as much as half, depending on the alloy). Fatigue limit refers to the number of times a material can be repetitively flexed before it fails. TITANUM matches or outperform most steel in fatigue resistance, even at welded joints (Nuclear-Power.net, NASA).

TITANIUM is classified into a range of grades by the American Society for Testing and Materials (ASTM). The first four grades are "commercially pure (CP)", containing less than 1% chemical impurities. CP TITANIUMs are more maleable than alloys, which made them attractive to early frame builders, but are weaker. Grade 9 TITANIUM, or 3al/2.5v, is an alloy now commonly used in bicycle frame production. The name indicates that it contains 3% aluminum and 2.5% vanadium, increasing its strength while maintaining relative ease of welding (Titanium Exposed).

| Metal - Alloy | Density | Modulus of Elasticity | Ultimate Tensile Strength | Source |

|---|---|---|---|---|

| TITANIUM------- 3al/2.5v | 4.5 g/cc - 0.162 lb/in3 | 095 GPa - 13780 ksi | 750 MPa - 108778 psi | Azom |

| ALUMINUM----- 6061 | 2.7 g/cc - 0.097 lb/in3 | 067 GPa - 10000 ksi | 310 MPa - 045000 psi | ASM |

| STEEL------------ 4130 | 7.9 g/cc - 0.284 lb/in3 | 205 GPa - 29700 ksi | 670 MPa - 097200 psi | ASM |

Due to a lack of variety in TITANIUM tubing available up until the late 1980s, TITANIUM's low MOE presented more problem than promise for early framebuilders. This limited tube selection, coupled with an initial tendancy to adhere to very traditional frame design parameters, virtually guaranteed that many of the earliest designs would suffer from excessive (and sometimes even dangerous) flexibity. On the flip side, however, those few early frames that were able to provide sufficient regidity were also recognized for their delightfully forgiving and supple rides. TITANIUM is still favored today for its ability to soak up road chatter and soften jolts from trail features.

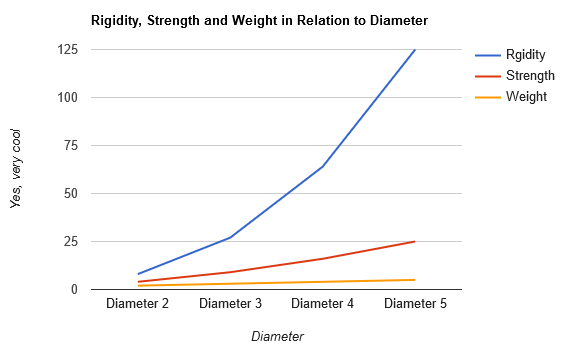

Being able to choose the ideal tube diameters and wall thicknesses is important for anyone wanting to build a bicycle frame, and can make all the difference when it comes to TITANIUM. Essentially, diameter matters because, all other things remaining equal, a tube's moment of inertia (rigidity) grows cubicly in perportion to diameter (for those who don't remember, a cubed number is multiplied by itself three times). Put simply, a relatively minor increase in diameter results in a major increases in rigidity.

Regarding modifications of tubing:

"[A.] If the diameter is multiplied by k but the wall thickness is not changed, the rigidity increases by a factor of approximately k3 and the strength by a factor of approximately k2 (Weight increases by a factor of approximately k.)

[B.] If the diameter is multiplied by k but the wall thickness is divided by k (so that the weight remains approximately the same) the rigidity increases by a factor of approximately k2 and the strength by a factor of approximately k." (Crispin Mount Miller)

The extreme relationship between diameter and rigidity is displayed in the graph at left, depicting scenario A described in the quote above: an increase in diameter while maintaining the same wall thickness. In order to visualize scenario B, ignore the blue line, make the red line "rigidity" and the yellow line "strength" (weight remains constant). This makes it easy to conceptualize some of the dynamics at play when switching from steel to TITANIUM as a building material. The effect of TITANIUM's lower MOE on a frame can be modulated by an increase in tube diameter, while TITANIUM's greater strength means that thin walls can be used, at which point you start seeing significant weight savings.

A really fun tubing safety calculator can be found at Roguefab.com, which allows you to test relationships between metal type, diameter, thickness and strength for yourself.

But everything we've covered so far is still only part of the picture!

If a designer has a wide range of shapes and thicknesses of tubing at her disposal, then TITANIUM's low MOE doesn't have to be something to engineer around... On the contrary, when taken in combination with TITANIUM's high fatigue resistance, the low MOE opens up all sorts of exciting possibilities for soft, or pivotless suspension designs!

All of the above considerations explain what makes TITANIUM interesting from a mechanical or engineering standpoint. Arguably, however, TITANIUM's appeal has always had its less tangible side. Several factors probably contribute to TITANIUM's mystique: its association with aerospace industries, its relative rarity and expense all certinly contribute. Personally, I like the look of the bare metal itself, polished or not, and I like that it won't scratch or chip in the same way as a painted frame will.

TITANIUM is frequently said to be completely corrosion resistant--properly speaking, however, TITANIUM is actually highly reactive to oxygen, and at room temperature the metal instantly forms a surface layer of TITANIUM dioxide in response to air exposure. It is this natural oxidized surface layer that is impervious to common corrosives like salt water. In this way, it's almost like TITANIUM grows its own armor! At welding temperatures, however, TITANUM is not only reactive to oxygen, but also to nitrogen, hydrogen, carbon and other impurities, producing oxides that ruin the structural integrity of welds. As a result, TITANIUM welding must take place in an extremely clean and air-purged environment, meaning either inside a vacuum chamber or using careful argon-gas shielding (Miller Welds). These requirements typically make TITANIUM constuction the preserve of well-resourced and highly-skilled outfits. TITANIUM frames can also be bonded together using chemical adhesives in order to avoid some of the complications of welding. Many large manufacturers experimented with bonded TITANIUM frames in the past, with results that tended to be underwhelming. However, advances in readily available epoxy adhesive technology might make the practice an attractive alternative to welding today, especially for small-scale builders. Lastly, it should be mentioned that TITANIUM can indeed be brazed, although this is a mysterious and lost art now.

Another aspect of TITANIUM's cool factor is, arguably, its association with specific builders. Steel and aluminum are used almost universally at this point, and few stand out for their unique mastery over these materials. Titanium, on the other hand, conjures names like Riva, Helfrich, Augspurger, Kellog. Likewise, certain logos are inextricably tied to the grey metal: LITESPEED's blocky yellow lettering or Merlin's sophisticated white. Just reading CLARK KENT on a downtube gets my pulse up. The example of Clark Kent is perhaps especially revealing in terms of TITANIUM's psychological associations. While detailed accounts of the company's history or their products are difficult to locate, surviving advertisements and the occasional review make clear that the name of the game was "cutting edge innovation." Everything was an experiment or an advancement in engineering: a marked departure from the (relative) traditionalism of the European bicycling old guard.

Still, one can legitimately wonder, has TITANIUM been eclipsed as a bike frame super material? Carbon fiber technology has certainly advanced and become more accessible, but it's difficult to make a comparison. At this point, fully custom carbon fiber frames are so rare as to make the concept almost seem oxymoronic: economical carbon construction is essentially a cookie-cutter industry. TITANIUM, on the other hand, is still a top choice for those custom frame builders who have the equipment necessary to cut and weld it. Likewise, carbon fiber can be made into shapes that resist formidable bending forces, but its surface wear and impact resistance still leave a lot to be desired. Of course, at the end of the day, academic arguments about the strength of various building materials can fall apart quickly in the face of physical endurance tests of real frames, which seem to confirm that unforseen weaknesses arising from obscure engineering considerations or imperceptible manufacturing defects sometimes have the last word.

If there's a TITANIUM killing metal out there, it might be something along the lines of Reynolds 953 Stainless Steel. With higher listed tensile strength than the most common TITANIUM used for bicycle frames (Grade 9 Ti 3Al 2.5V), along with a MOE roughly the same as other steels, it is somewhat less environmentally destructive to produce, and doesn't require the same purging procedure. And, yes, it has proven that it can build a light bike. That having been said, 953 doesn't have anything close to the corrosion resistance of TITANIUM, and a few builders who worked on early tubesets reported cracking problems and the like. While some of the cracking issues seem to have been dealt with, it's still not an easy steel to work with. As such, 953 is showing no signs of dethroning TITANIUM. As for new wonder alloys, who knows what the future brings.

If there's a TITANIUM killing metal out there, it might be something along the lines of Reynolds 953 Stainless Steel. With higher listed tensile strength than the most common TITANIUM used for bicycle frames (Grade 9 Ti 3Al 2.5V), along with a MOE roughly the same as other steels, it is somewhat less environmentally destructive to produce, and doesn't require the same purging procedure. And, yes, it has proven that it can build a light bike. That having been said, 953 doesn't have anything close to the corrosion resistance of TITANIUM, and a few builders who worked on early tubesets reported cracking problems and the like. While some of the cracking issues seem to have been dealt with, it's still not an easy steel to work with. As such, 953 is showing no signs of dethroning TITANIUM. As for new wonder alloys, who knows what the future brings.

| What is Modulus of Elasticity (MOE)? | ||||

|---|---|---|---|---|

| What does 3al/2.5v refer to? | ||||

| What is the best metal? |

https://cimg6.ibsrv.net/gimg/bikeforums.net-vbulletin/841x1087/bike_world_feb_1974_titanium_metal_p35_50pct_0e9c687a723a012afc5f977d6d2b6176f31a9978.jpg

Bike World Magazine February 1974 discussion on TITANIUM.

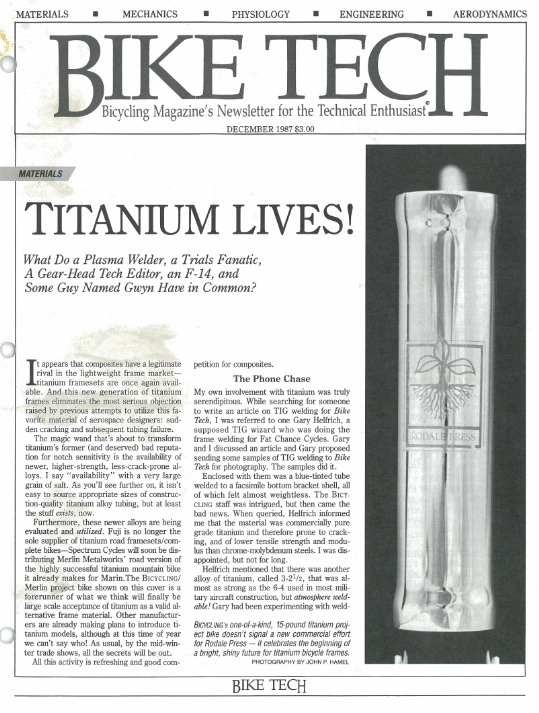

Bike Tech, December 1987, “Titanium Lives!”, by Jim Redcay. This fascinating article explores the difficulties of obtaining and shaping 3al/2.5v TITANIUM tubing in 1986/7, and contains a WEALTH of techical data on frame construction at that time. A tantalizing peek at the state of the industry immediately leading up to the big TITANIUM boom of 1988. Sourced from Rob Vandermark's blog.

https://early-titanium-archive.neocities.org/mcmahon2.png

McMahon Racing Cycles discusses TITANIUM, probably from 1989.

https://archive.ibiscycles.com/support/technical_articles/metallurgy_for_cyclists/the_titanium_advantage/

This articles was written by Scot Nicol and appeared in VeloNews magazine in 1994. Previously hosted on the Ibis Cycles website.

Titanium Today, Consumer Edition, Issue 6, No. 1.

This brief article was written on the occasion of the republication of the Ti-3Al-2.5V Seamless Tubing Engineering Guide in E-book format. The article does a good job summarizing the benefits of 3al/2.5v alloy and recounts how the author of the Guide had a number of interesting contacts with the bicycle world, including that dynamic duo, Pino Morroni and Cecil Behringer! No longer available online :(